Can preserving your favorite sweets make them tastier while lasting years longer? Imagine biting into a treat that crunches like a crisp autumn leaf yet bursts with intensified fruity or chocolatey flavors. This isn’t magic—it’s the science of modern food preservation.

Traditional methods often leave snacks soggy or bland, but freeze-dried candies defy expectations. By removing moisture at ultra-low temperatures, this process locks in freshness while transforming textures into airy, melt-in-your-mouth delights. The result? A lightweight, mess-free snack that retains its original sweetness without refrigeration.

Through this guide, you’ll discover how specific sugar structures react to temperature changes and why certain confections become shelf-stable for decades. We’ll explore both commercial techniques and home-friendly approaches using everyday tools. Whether you’re a dessert enthusiast or meal-prep warrior, these insights will change how you think about sweet preservation.

Key Takeaways

- Freeze-drying removes 98% of moisture, creating shelf-stable treats lasting up to 25 years

- Flavors become more concentrated while colors stay vibrant

- Gummy bears and marshmallows transform into crispy, airy versions of themselves

- No added preservatives needed—just science-driven dehydration

- Home methods using dry ice can achieve similar results to industrial machines

An Introduction to Candy Preservation and Freeze Drying

What if your go-to snacks could stay fresh for decades while tasting even better? Freeze-drying unlocks this possibility, turning ordinary treats into lightweight, flavor-packed wonders. Originally developed during World War II to preserve medical supplies, this method soon revolutionized how we store fruits—and now sweets.

Understanding Freeze-Drying and Its Origins

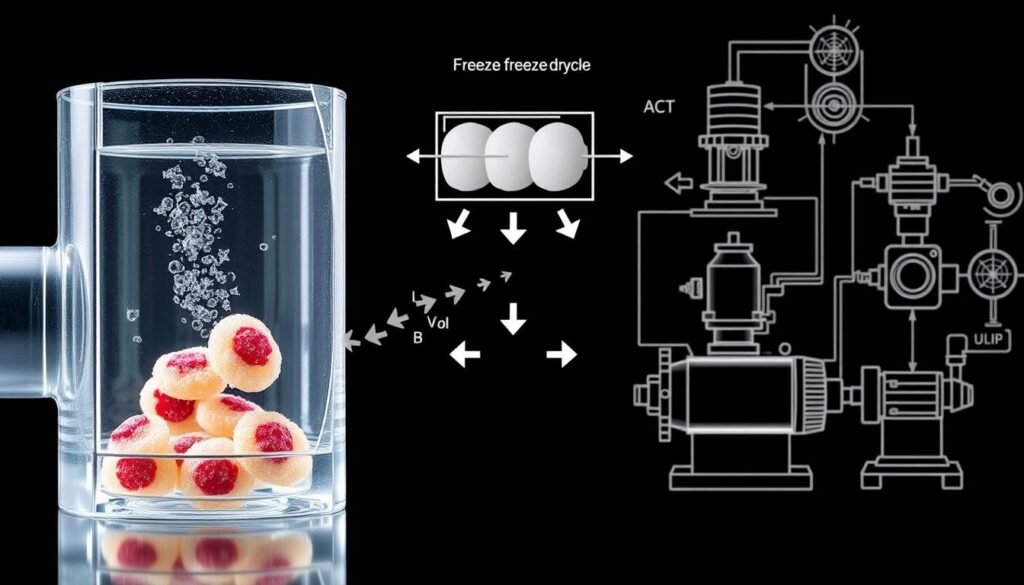

The technique works through sublimation, where frozen water turns directly into vapor under low pressure. NASA later adopted it for astronaut meals, but candy creators saw potential. By removing 98% of moisture, textures transform without sacrificing taste. Gummies become crisp, while chocolate takes on a delicate, meltaway quality.

Why Candy Lovers Should Be Excited

Enthusiasts rave about intensified flavors—strawberry bursts taste sweeter, citrus zings sharper. Unlike traditional drying, colors stay vibrant, and nutrients remain intact. Best of all? No preservatives. The vacuum-sealed process does all the work.

Home methods using dry ice let anyone make freeze-dried candy. Brands now offer rainbow-colored marshmallows and tangy sour belts with 25-year shelf lives. It’s not just about longevity—it’s a whole new way to enjoy sweets.

The Science Behind Freeze-Drying Candy

What transforms chewy gummies into crispy delights that dissolve like snowflakes on your tongue? It’s all about controlled physics. This method uses extreme cold and vacuum power to rework sweets at a molecular level while keeping their essence intact.

How Temperature and Pressure Transform Treats

First, confections get chilled to -40°F—colder than Antarctica’s winter. This deep freeze locks sugars into rigid structures. Next, a vacuum chamber pulls air pressure down to near-space conditions. Here’s where magic happens: solid ice skips the liquid phase, becoming vapor through sublimation.

| Stage | Temperature | Effect on Texture |

|---|---|---|

| Freezing | -40°F | Creates crystalline framework |

| Vacuum | 0.006 atm | Removes 98% moisture |

| Sublimation | Gradual warming | Preserves cellular structure |

The Role of Sublimation in Preserving Flavor

Unlike baking or frying, this technique avoids heat damage. Flavor molecules stay trapped in sugar matrices, becoming more concentrated. A strawberry chew’s tanginess amplifies as water exits, leaving pure fruit essence behind.

Nutrients also survive the journey. Vitamin C in citrus treats remains stable, just like in fresh produce. This explains why freeze-dried options often taste brighter than their original forms—nature’s goodness, intensified.

“It’s like pressing pause on freshness while hitting fast-forward on taste,” explains food scientist Dr. Elena Torres.

The result? Treats with an airy crunch that still burst with authentic sweetness. From rainbow marshmallows to tart apple rings, every bite becomes a celebration of science meeting dessert.

does freeze drying candy make i: Unpacking the Process

Ever wonder how gummy worms turn into crunchy, cloud-like snacks? The answer lies in three precise stages that redefine texture and taste. Let’s break down the steps transforming ordinary sweets into shelf-stable marvels.

Stage 1: Deep Freeze

Confections chill at -40°F, colder than polar winters. This locks sugars into rigid frameworks, preventing collapse during dehydration. Hard candies and marshmallows solidify evenly, while softer treats like taffy stabilize their shapes.

Stage 2: Vacuum Chamber Activation

Air pressure drops to 0.006 atm—like conditions on Mars. Ice crystals skip melting and vaporize directly, a phenomenon called sublimation. Moisture exits without distorting designs or dissolving colors.

| Phase | Key Factor | Result |

|---|---|---|

| Freezing | -40°F | Stabilizes structure |

| Vacuum | Ultra-low pressure | Removes 98% water |

| Sealing | Oxygen-free packaging | Extends shelf life |

Stage 3: Flavor Lock

As water vanishes, natural sugars and acids concentrate. A lemon drop’s zing sharpens, while caramel notes deepen into richer profiles. No heat means no burnt aftertaste—just pure, amplified sweetness.

Home enthusiasts replicate this using dry ice and airtight containers. While industrial machines guarantee consistency, DIY methods let you experiment with textures. Pro tip: Thinner slices dry faster, creating crispier results.

“Controlling pressure is the secret sauce—it’s why store-bought versions have that perfect crunch,” notes confectionery engineer Marco Ruiz.

Whether using professional gear or kitchen hacks, the goal remains: preserve whimsical shapes while unlocking bold new taste dimensions. Next, we’ll explore how these changes delight your taste buds.

Exploring Unique Textures and Intensified Flavors

Bite into a once-chewy gummy bear, and it shatters like glass—then dissolves into a fruity explosion. This magical transformation defines freeze-dried treats, where every piece becomes a playground of unexpected sensations. The process doesn’t just preserve sweets—it reinvents them.

Texture Transformation: From Chewy to Crunchy

Imagine sinking your teeth into a marshmallow that crackles like cereal. Moisture removal turns soft confections into airy, lattice-like structures. Skittles lose their waxy shell, revealing a delicate crunch that amplifies their tangy core. Even chocolate-covered raisins gain a satisfying snap while maintaining creamy centers.

| Original Texture | Freeze-Dried Result | Sensory Experience |

|---|---|---|

| Gummy (elastic) | Crisp (porous) | Lightweight crunch |

| Chewy (dense) | Flaky (layered) | Melt-on-tongue effect |

| Sticky (taffy-like) | Brittle (honeycomb) | Quick dissolution |

Flavor Intensification and Concentration

Water’s exit acts like a flavor magnifier. Natural sugars in strawberry belts become 3x sweeter, while citric acid in lemon drops punches with laser focus. A single sour patch kid delivers a tartness that lingers longer than its original form. “It’s like tasting candy for the first time—your brain can’t believe the intensity,” says pastry chef Amara Chen.

This alchemy works across categories: chocolate gains earthy depth, caramel notes turn richer, and fruit flavors achieve near-jam-like potency. Each bite becomes a concentrated burst, turning casual snacking into an adventure for the taste buds.

DIY Guide: How to Freeze Dry Candy at Home

Turn your kitchen into a flavor lab with two accessible methods for creating shelf-stable sweets. Whether using specialized equipment or everyday tools, these techniques let anyone craft crispy, intensified treats.

Freeze Dryer Method: Step-by-Step Setup

Start with a countertop freeze dryer—Harvest Right models work best. Slice candies into ¼-inch pieces for even drying. Pre-freeze them overnight on parchment-lined trays to speed up the process.

Load trays into the machine and select Candy Mode. This setting maintains -30°F while cycling pressure for 12-24 hours. Check progress periodically—properly dried treats should snap cleanly, not bend.

| Equipment | Time | Key Tip |

|---|---|---|

| Freeze dryer | 12-24 hrs | Use silicone mats to prevent sticking |

| Vacuum sealer | 5 mins | Add oxygen absorbers for long storage |

DIY Techniques Without a Freeze Dryer

No machine? Grab dry ice and a cooler. Layer candies between newspaper, leaving space for vapor flow. Wear insulated gloves—this gets cold. Seal the cooler for 72 hours, letting sublimation work its magic.

For smaller batches, try a deep freezer. Place sliced sweets on wire racks and rotate every 8 hours. Results take 5-7 days but preserve more nutrients than oven methods.

“Patience pays off—rushing leads to chewy centers,” advises home chef Lila Nguyen.

Troubleshooting tip: If treats stay sticky, extend drying time or reduce piece thickness. Store in airtight jars with silica packets to maintain crunch.

Freeze-Dried Candy: Benefits, Shelf Life, and Nutritional Impact

Crunchy, light, and bursting with taste—freeze-dried sweets redefine snacking. These treats offer practical advantages that go beyond novelty, combining science with sustainability for modern consumers.

Long Shelf Life Without Chemical Preservatives

Moisture removal is the superhero here. By eliminating 98% of water content, the process stops microbial growth dead in its tracks. Popular brands like Cosmic Crunch report shelf lives exceeding 5 years—no artificial additives needed. Compare that to regular gummies, which often develop mold within months.

| Treat Type | Traditional Shelf Life | Freeze-Dried Shelf Life |

|---|---|---|

| Fruit Chews | 6-9 months | 5+ years |

| Chocolate Pieces | 12 months | 3 years |

Managing Portion Control with Intense Flavors

One piece packs a punch. The flavor concentration means you’ll naturally eat less while feeling satisfied. A study in Food Science Today found participants consumed 40% fewer freeze-dried sour patches compared to standard versions.

Nutritionally, these treats retain original sugar levels but skip synthetic preservatives. Storing them is simple: keep in airtight containers away from heat. For those exploring healthier snack alternatives, the combo of reduced waste and cleaner ingredients makes a compelling case.

“The airy texture slows down eating, helping people savor each bite mindfully,” notes nutritionist Dr. Rachel Kim.

From camping trips to lunchboxes, these candies deliver adventure-ready crunch without compromising on taste or ethics. It’s snacking evolved—one crispy piece at a time.

Trends, Market Growth, and Innovative Uses in the United States

The snack aisle is undergoing a crunchy revolution. Freeze-dried sweets now command 17% of the specialty candy market, with searches for “buy freeze-dried candy” tripling since 2022. This boom reflects shifting consumer priorities—bold experiences, sustainability, and pantry-ready convenience.

Emerging Freeze-Dried Candy Options and Popular Brands

Innovators are pushing boundaries with unexpected flavors and formats. Crunchster’s mango-chili gummies and Cosmic Bites’ layered chocolate-orange disks dominate social media feeds. Smaller brands like Lunar Sweets gain traction with nostalgic twists—think astronaut ice cream sandwiches.

| Brand | Specialty | Shelf Life |

|---|---|---|

| Crunchster | Spicy-sweet combos | 5 years |

| SnackNova | Organic fruit chews | 3 years |

| Zero-G Treats | Space-themed shapes | 7 years |

Environmental and Nutritional Considerations

Eco-conscious shoppers drive demand for minimal packaging. Many companies now use compostable wrappers, reducing landfill waste by up to 40% compared to traditional candy bags. Nutritionally, these options retain original nutrients while offering portion-controlled intensity—a win for mindful snackers.

A 2023 survey revealed 68% of buyers choose freeze-dried treats for their extended freshness and reduced food waste. “I love that one bag lasts months without going stale,” shared Colorado-based customer Jenna Rollins in a recent interview.

“The texture adventure keeps me reaching back into the pouch—it’s like rediscovering childhood favorites through a sci-fi lens.”

From camping trips to lunchboxes, these airy confections prove that innovation and responsibility can coexist deliciously. Ready to join the crunch? Explore store shelves or try the dry candy home method for a DIY twist.

Conclusion

Snacking enters a new era with shelf-stable confections that defy time and taste expectations. Through sublimation’s precise dance of ice and vapor, ordinary sweets morph into airy delights packed with amplified flavor. The science is clear: removing water preserves vibrant colors, locks in nutrients, and creates that signature crunch fans adore.

Freeze-dried treats offer more than novelty—they’re pantry heroes. With shelf lives stretching years and zero preservatives, these lightweight options cater to adventurers and homebodies alike. Brands now deliver everything from tangy fruit belts to chocolate disks that dissolve like edible clouds.

Ready to experience the shift? Whip up batches using dry ice or explore specialty stores stocked with innovative options. Share your creations online using #CrunchRevolution—the community thrives on swapping texture hacks and flavor triumphs.

Whether you crave nostalgic sweets reimagined or seek eco-friendly snacking, this preservation method turns ordinary moments into extraordinary bites. The future of indulgence isn’t just sweet—it’s crisp, concentrated, and endlessly surprising.